DPF / EGR /AdBlue Servis

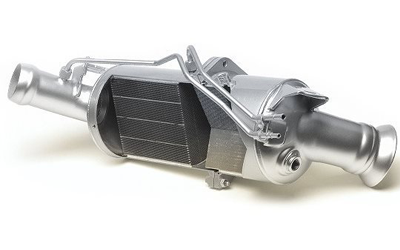

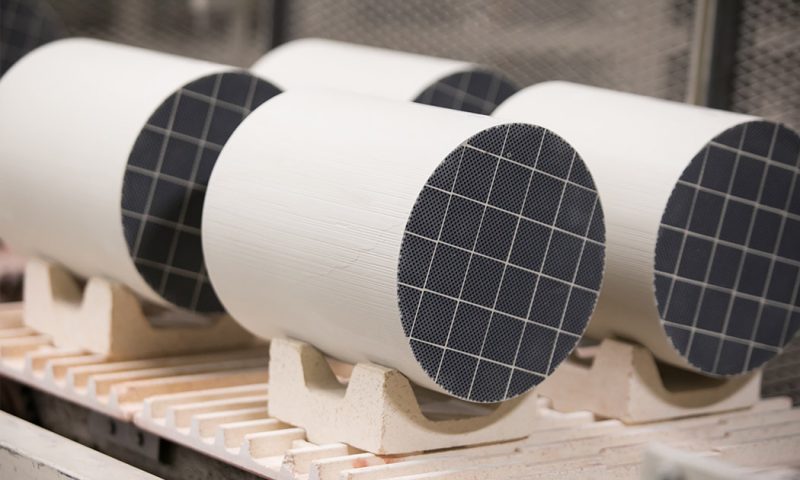

DPF (Diesel Particulate Filter)

What is DPF (Diesel Particulate Filter)? How does it work?

Today, we know that vehicle emission values have hardened too much due to weather conditions. Manufacturers use a muffler-like unit used in diesel vehicles to comply with these norms.

These units, which are mandatory in some Euro 4 vehicles but Euro 5 and Euro 6 vehicles, are the first place where the gases discharged from the engine pass through this porous very narrow place first to reduce the carbon ratio, because the carbons that cannot pass remain in the filter, because they do not burn out without seeing the high exhaust temperature. they wait to burn

Pressure sensors measure the level of soot residue in the diesel particulate filter and when the critical soot level is detected in the filter and the appropriate conditions are established, the regeneration process begins. this process dpf

When it reaches 600~650 °C, the carbons start to burn and remain in process under the control of pressure sensors according to the occupancy rate.

In order to prevent clogging of the DPF, the particles accumulated in the filter must be cleaned by burning regularly.

Generally, the DPF clogs for the following reasons:

- Low quality fuel,

- Long-term use of vehicles at low speed and in stop-and-go traffic,

- Running the vehicle at idle for a long time,

- Wrong specification engine oil use.

The DPF, which is found in all new diesel vehicles, may not be cleaned even with the regeneration process if the necessary precautions are not taken and may need to be replaced.

Adblue Nedir ?

What is Adblue?

Adblue; It is a non-toxic substance produced by adding demineralized water, consisting of 32.5% purified urea, which is water-clear, used to chemically reduce the Nox-emission of diesel fueled heavy-duty vehicles. Adblue is a brand and adblue brand rights are protected by the Automobile Industry Association. AdBlue is a registered trademark of VDA (Verband der Automobilindustrie) and is used under license.

What is Adblue used for?

It is used to clean the gases produced by AdBlue scr Catalysts and to reduce the nitrogen oxide emissions created by diesel fuel heavy duty vehicles. It reduces the gas output, ie Nox-emission, by an average of 90%.

Is Adblue harmful?

AdBlue is not an explosive substance. It is harmful to the environment and is classified in the minimum risk category of portable liquids. AdBlue has abrasive properties. Certain materials are required for the use and storage of Adblue.

Adblue usage

Thanks to AdBlue technology, toxic gases are cleaned. It has been used only in commercial vehicles until today. It is used for trucks and trailers to reach the Euro5 norm.

Features of AdBlue

- AdBlue is non-toxic and does not pose any risk to humans, animals or the environment if used properly.

- Precautions to be taken while working with AdBlue include avoiding contact with skin and eyes. If Adblue is spilled on the floor, it presents a slipping hazard.

- Cleaning methods are to collect mechanically and collect in suitable containers for disposal.

- AdBlue is not flammable.

- AdBlue – starts to freeze at 11.5 °C.

- AdBlue can also be used after freezing. After AdBlue melts, it can be used without any problems.

- Washing with water is the best way to dispose of crystallization or spills.

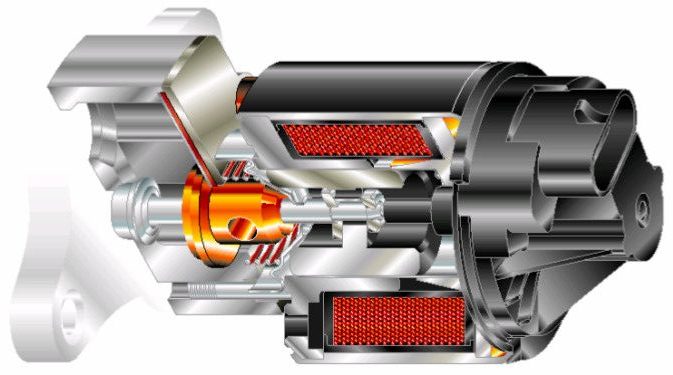

What is EGR ?

Exhaust gas recycling (EGR) is a system that aims to reduce the heat generated as a result of combustion by giving some of the exhaust gas back to the cylinders, this keeping the environmentally harmful nitrogen oxide gases (NOx) under control. It is widely used in today’s gasoline and diesel engines. Mixing the fresh air entering the engine with the burnt exhaust gas reduces the combustion temperature and (in diesel engines) the amount of excess oxygen. Since the formation of NOx gases is accelerated at high temperatures, controlling the temperature also allows the formation of harmful NOx gases to be controlled. The EGR valve is the part that separates the unburned oxygen from the exhaust gas and sends it back to the combustion chambers.

What is the EGR Valve working system?

The EGR valve separates and sends the unburned oxygen from the exhaust gas in the combustion chambers. In this way, a better quality explosion takes place in the combustion chambers.

What are EGR Valve malfunctions?

EGR valve can soot over time due to exhaust gases. Accordingly, the need for cleaning the EGR valve arises. The accumulation of soot, similar to coal dust, can cause this part to malfunction and deteriorate over time. Therefore, EGR valve cleaning and maintenance should be done at the right time and should be changed when necessary.

What problems will arise if the EGR valve is dirty or broken?

Usually, it can manifest itself as a jerky or non-starting vehicle engine after EGR Valve contamination or deterioration. Subsequently, the increased fuel consumption will increase noticeably. Symptoms such as low traction, shaking or misfire while in motion may be an indication that the EGR Valve is dirty. If it is not intervened in time, it is possible that other problems will arise. Therefore, the EGR valve should be cleaned as soon as possible.

How to change or clean the EGR valve?

The EGR valve is a part connected between the air filter and the exhaust manifold. An easier working area is created by opening some places around this piece for change. Then the air filter bowl is disassembled and the joint is prepared for disassembly. The EGR valve is disconnected at the manifold connection, a new one is installed and the parts are collected. If cleaning is to be done, the inside of the EGR valve is first cleaned with the help of a brush and the coarse dirt is removed. Then, the soot in special sprays and liquids is completely cleaned. Then, all the soot remaining on the EGR valve, which is kept in the dirt removing liquids for a while, is separated. Then it is dried and the remaining residues are cleaned with a spray for the last time. Then the manifold connection is made and the assembly process is completed. EGR valve cleaning or replacement requires serious skill. If such procedures are not done correctly, your vehicle may cause bigger problems.